TMT Bar

“TMT Bar” typically refers to Thermo-Mechanically Treated bars, which are high-strength reinforcement bars used in construction. These bars undergo a series of processes including quenching and tempering, which impart them with enhanced strength and ductility compared to traditional mild steel bars. TMT bars are widely used in reinforced concrete structures for their superior properties in terms of strength, ductility, and weldability. They are commonly used in building construction, bridges, dams, and other infrastructure projects.

M.S. Channels

M.S. Channels, often referred to simply as “channels,” are structural steel sections with a distinctive “C” shape when viewed in cross-section. They are commonly used in construction and engineering projects to provide support and stability to structures. M.S. stands for Mild Steel, indicating the type of steel used in their construction.

Channels are versatile components that can be used in various applications, such as framing for buildings, bridges, and other infrastructure projects. They are often used as beams, columns, or purlins, depending on the specific requirements of the project. The dimensions and specifications of M.S. channels can vary widely, allowing for customization to suit different structural needs.

M.S. Windows Section

“M.S. Windows Section” typically refers to Mild Steel (M.S.) sections used in the fabrication of window frames. These sections are designed to provide structural support and framing for windows in buildings.

Mild steel is a popular choice for window sections due to its strength, durability, and affordability. These sections come in various shapes and sizes, such as L-sections or Z-sections, depending on the specific requirements of the window design and the load-bearing capacity needed.

M.S. window sections are commonly used in residential, commercial, and industrial buildings for their ability to withstand various weather conditions and provide a secure frame for windows. They can be welded, bolted, or otherwise joined to create the desired window frame configuration.

RS Joist

“RS Joist” typically refers to Rolled Steel Joists, which are structural steel beams with a distinctive “I” or “H” shape when viewed in cross-section. They are commonly used in construction and engineering projects to provide support and load-bearing capabilities for floors, roofs, and other structural elements.

RS Joists are manufactured by rolling steel at high temperatures, which results in a profile that provides excellent strength-to-weight ratio and structural integrity. They are often used in conjunction with other structural components such as columns and beams to form a framework for buildings, bridges, and other structures.

RS Joists come in various sizes and specifications to suit different project requirements. They are widely used in residential, commercial, and industrial construction due to their versatility, durability, and cost-effectiveness.

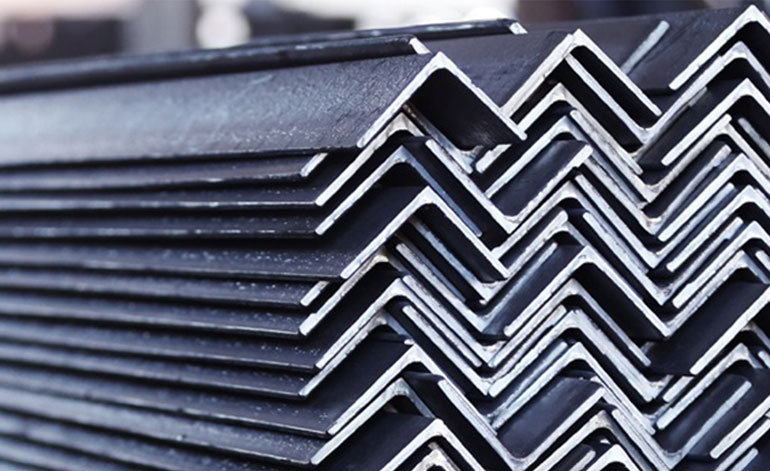

M.S. Equal Angles

M.S. Equal Angles, also known as Mild Steel Equal Angles, are structural steel sections with equal legs that form a right angle when joined together. They are commonly used in construction and engineering projects for various applications, including structural framing, support brackets, and reinforcements.

These angles are manufactured from mild steel, offering a balance between strength and affordability. The equal leg lengths make them suitable for applications where right angles are required, such as in frames, braces, or supports. They come in a range of sizes and thicknesses to accommodate different load-bearing requirements.

M.S. Equal Angles are widely used in buildings, bridges, infrastructure projects, and industrial applications due to their versatility, ease of fabrication, and structural stability. They can be welded, bolted, or otherwise connected to other structural components to create sturdy and reliable frameworks.

M.S. Plates

M.S. Plates, or Mild Steel Plates, are flat steel sheets of varying thicknesses made from mild steel. They are one of the most common forms of structural steel used in construction, manufacturing, and various industrial applications.

M.S. Plates are utilized for a wide range of purposes due to their versatility, strength, and affordability. They can be cut and shaped easily to suit specific requirements, making them suitable for applications such as:

Structural components: M.S. Plates are often used as base plates, floor plates, and stiffeners in structural steel frameworks for buildings, bridges, and other infrastructure projects.

Manufacturing: They serve as raw materials for fabricating machinery, equipment, storage tanks, and various industrial components.

Automotive industry: M.S. Plates are used in the manufacture of vehicle bodies, chassis, and structural components.

Shipbuilding: They are used in constructing ship hulls, decks, and bulkheads due to their strength and corrosion resistance.

Construction machinery: M.S. Plates are employed in manufacturing construction equipment such as cranes, excavators, and bulldozers.

M.S. Plates are available in various sizes, thicknesses, and grades to meet the diverse needs of different applications, and they can be further processed through cutting, welding, bending, and other fabrication techniques to achieve the desired shapes and dimensions.

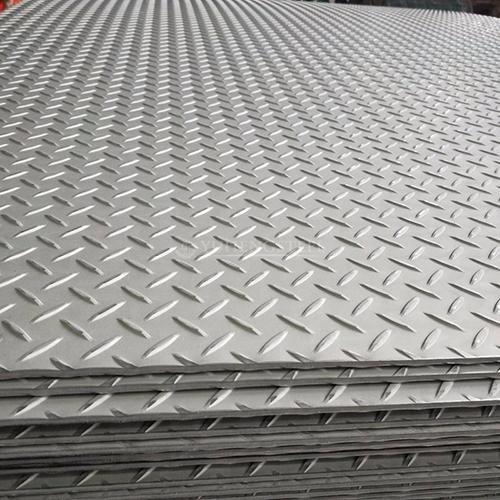

M.S. Chequered Plates

M.S. Chequered Plates, also known as Mild Steel Chequered Plates or M.S. Checker Plates, are flat steel plates with a pattern of raised projections or “chequers” on one surface. These raised patterns typically form a diamond or other geometric shapes, providing improved traction and slip resistance, especially in areas prone to moisture or oily conditions.

M.S. Chequered Plates are commonly used in various industries and applications, including:

Flooring: They are frequently used as floor plates in industrial and commercial settings such as factories, warehouses, ramps, staircases, and walkways to prevent slipping accidents.

Vehicles: They are utilized as floor plates in trucks, trailers, and other vehicles to provide a non-slip surface for loading and unloading cargo.

Construction: M.S. Chequered Plates are employed as decking material for scaffolding, platforms, and temporary structures at construction sites.

Structural components: They serve as base plates or reinforcement plates in structural steel frameworks, providing additional strength and stability.

M.S. Chequered Plates are available in various thicknesses, sizes, and patterns to suit different applications and load-bearing requirements. They are typically made from mild steel due to its affordability, durability, and weldability. Additionally, they can be further processed through cutting, bending, and welding to meet specific project needs.

M.S. Flats

M.S. Flats, also known as Mild Steel Flats or M.S. Flat Bars, are rectangular steel bars with a flat surface and uniform thickness throughout their length. They are commonly used in construction, manufacturing, and various other industrial applications.

M.S. Flats are versatile structural components with a wide range of uses, including:

Construction: They are used as structural members in frameworks for buildings, bridges, and infrastructure projects. M.S. Flats are often employed as base plates, braces, and stiffeners due to their strength and stability.

Fabrication: They serve as raw material for fabricating machinery, equipment, brackets, and support structures in manufacturing industries.

Furniture: M.S. Flats are utilized in the manufacture of furniture components such as table legs, bed frames, and shelving due to their durability and ease of fabrication.

Automotive industry: They are used in vehicle manufacturing for applications such as chassis components, brackets, and support structures.

Agricultural machinery: M.S. Flats are employed in the construction of agricultural equipment such as plows, cultivators, and harrows.

M.S. Flats are available in various widths, thicknesses, and lengths to meet the specific requirements of different applications. They can be further processed through cutting, bending, drilling, and welding to achieve the desired shapes and dimensions for specific projects.

M.S. Squares

M.S. Squares, Rounds, and TOR Steel are all different types of mild steel products used in construction and various other applications:

M.S. Squares: M.S. Squares, also known as Mild Steel Square Bars, are square-shaped steel bars with uniform width and thickness. They are commonly used in construction for various structural and fabrication purposes, such as braces, supports, and framework components. M.S. Squares are also utilized in manufacturing machinery, equipment, and furniture components.

M.S. Rounds: M.S. Rounds, or Mild Steel Round Bars, are cylindrical steel bars with a circular cross-section. They are widely used in construction, manufacturing, and engineering applications, including shafts, axles, fasteners, and structural components. M.S. Rounds are also employed in the fabrication of machinery, automotive parts, and agricultural equipment.

TOR Steel: TOR Steel, also known as High-Strength Deformed Steel Bars (HSD Bars), are steel bars with surface projections or deformations designed to enhance the bond strength with concrete. TOR Steel bars are commonly used in reinforced concrete structures such as bridges, buildings, and foundations. They provide increased strength and ductility to the concrete elements, enhancing their load-bearing capacity and resistance to cracking.

These mild steel products come in various sizes, diameters, and grades to suit different applications and load-bearing requirements. They are typically manufactured through hot rolling processes and can be further processed through cutting, bending, and welding to meet specific project needs.